25 Year Warranty for Network Cabling Installations

25 Year Warranty for Network Cabling Installations

We are very excited to announce that all our clients, where we install a new network cable infrastructure into their property, will be able to enjoy peace of mind with a 25-year warranty.

This warranty not only includes the necessary parts but also covers the cost of any labour required, to repair or replace a failed component.

In this blog we detail some of the elements of our data network implementations that allow our clients to benefit from this fantastic 25-year warranty. It will include information about the first step in any installation which is our professional network design. It will then cover some of the key components of our intelligent installation service. We will then discuss the different types of cable testers available and how we utilise only the highest level of comprehensive cable testing for our installation work. Finally, we will highlight some of the high-quality cable and cabling infrastructure components we use as part of our network implementations.

By the end of the blog, you will appreciate why a data network installed by Automated Spaces is a long-term sound investment.

1. Professional Network Design

NETWORK DESIGN YOU CAN RELY ON

When we design a network for a smart home you can rest assured that we comply with the relevant British Standards Institute (BSI) code of practice

[1] and when appropriate we incorporate recognised industry best practises

[2].

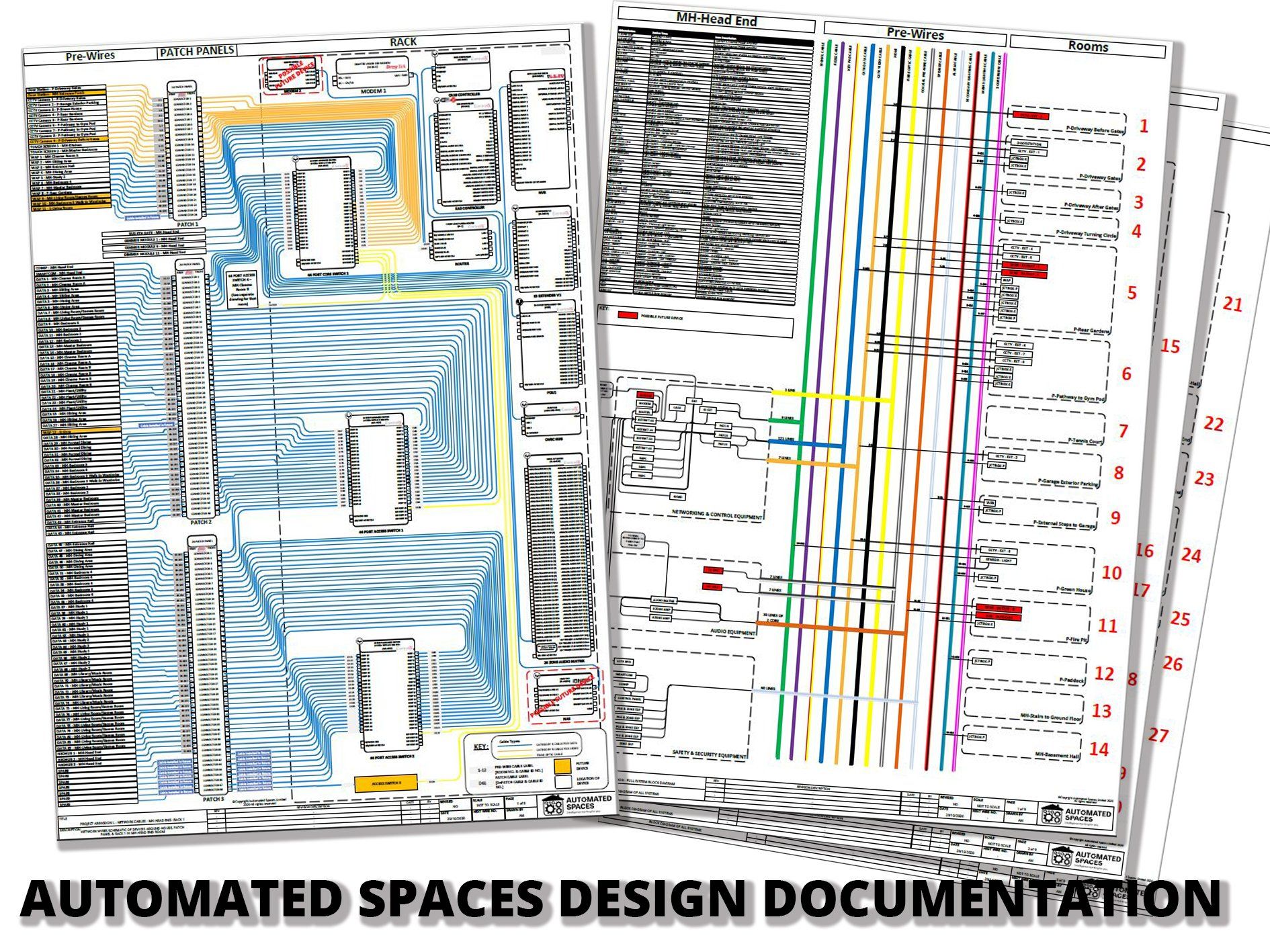

In most project situations, we will implement a star topology for your data network. This means that we will implement a centralised panel, located in a room called the ‘Head End’, from which cables will span out across the property to their intended location e.g., to the back of a data socket on a wall.

Subsequently between the panel and any equipment rack we install we will utilise a loom of patch cables. This means that should you ever wish to sell the property, and take your rack-based equipment with you, that there will be a neat panel left on the wall that any prospect buyer could easily use in the future. Meaning that any cable installation could be viewed as a long-term asset and thus a worthwhile investment in your property.

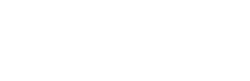

Our comprehensive design methodology will identify all those locations around your property where a data cable is required, as well as all the necessary rack-based equipment required to facilitate your networking infrastructure. We will then produce thorough documentation that will include:

- A schedule of the data cables to be installed that summaries all the relevant details associated with the individual cables; location of both ends, the type of device that the cable will be connected to at both ends, etc.

- Schematic drawings showing the individual component interconnectivity between the end point devices around the property and the central panel in the Head End as well as between the panel and the rack-based equipment

- Plans showing the various elements in the Head End as well as the various elements in each room/controlled zone and the associated pre-wires to connect them together

References:

[1] British Standards Institute (BSI):

- BS EN 50173-4:2018 Information technology. Generic cabling systems. Homes

- PAS 35491:2017 - Design and installation of telecommunications and broadcast infrastructure within the home. Code of practice

[2] CEDIA:

- Smart Home Infrastructure Recommended Guidelines

- Infrastructure Cabling for Voice, Data and Video

2. Intelligent Installation Service

SAFE AND EFFICIENT ONSITE INSTALLATION

We utilise an installation methodology that not only promotes both safe working practises but also introduces efficiencies that the reduces the time required onsite.

The methodology has been designed, through continual refinement, so that we can work in a way that minimises all the risks associated with cabling installation issues/errors/faults delaying your overall construction project timeline.

One of the key steps is not relying on ‘just-in-time’ deliveries being made to site. Instead, all the required cable and components will be ordered in advance and delivered to one of our secure locations several weeks in advance of being required onsite. This minimises the risk of supply chain stock level or courier/delivery issues causing a delay to the other trades on the work onsite.

The initial activity, of the 1st Fix cable installation, will involve a walk around the site with the client and main contractor to agree the final locations for all components that need to be installed in each room. These locations will be physically identified onsite and fully documented for future reference.

Once all cables have been correctly installed, to their relevant locations around the property from the centralised panel, they will then be terminated in situ. This will then allow us to fully test the cables prior to the walls in the property being sealed up and plastered over. This reduces the risk of finding a faulty/damaged cable after the main contractor has completed their painting and decorating 2nd fix activities. Therefore, this reduces the risk of potentially needing to chase out finished walls/ceilings to install replacement cables. With all the disruption, dust and delay that this additional work would entail.

3. Comprehensive Cable Testing

A CABLE YOU CAN TRUST

An installed cable is not a cable you can rely on or trust until it has been fully tested. There are 3 general levels of data cable testing that come with increasing rigour and requirements to pass. It is only the highest level of testing that can confirm if a cable has complied with the performance requirements of the relevant International, European or British standards.

The 3 categories of testing are as follows:

- Verification (lowest level of testing)

- Qualification

- Certification (highest level of testing)

Verification testing

A data cable will typically have 8 individual cable cores inside of the main outer plastic cable jacket. These 8 cores need to be installed in a specific sequence at both ends of the cable when it is terminated into either a device or wired into a data plug.

A verification test simply checks that each of the 8 individual cores have not been physically cut along the length of the cable (i.e., there is still end-to-end continuity along the cable), and the 8 cores have been terminated in the correct sequence at both ends.

Typically, a verification testing tool will cost between £30 - £350+Vat depending on the number of accessories.

Qualification testing

A qualification test is a step up from a verification test, along with checking the continuity of the cores and that they have been terminated in the correct sequence, it will also test if the cable can support the bandwidth requirements of the network and applications i.e., will the cable support certain data transmission rates.

Typically, a qualification testing tool will cost around £1,500+Vat depending on the number of accessories.

Certification testing

A certification test is the most stringent type of testing. Along with carrying out the checks that a verification and qualification tester would do, it also confirms that the cable complies with the performance requirements of the relevant International, European or British standards. The certification tester will also provide a detailed report of the results from the testing for each cable.

Typically, a certification testing tool will cost between £6,500 - £10,000+Vat depending on the number of accessories.

At Automated Spaces we have invested a significantly sum in our testing tools to ensure that we can comprehensively test our work and provide our clients with the peace of mind that the cables we install will perform as required. Along with numerous verification tools we also have purchased the highest level of cable tester, a cable certification tester. We use the cable certification tester on our client cable installations.

4. High-quality Cable and Cabling Infrastructure Components

NOT ALL DATA CABLES OR DATA CABLING COMPONENTS ARE BORN EQUAL

Firstly, a good quality data cable’s internal conducting 8 cores will be made of solid copper whereas a poor-quality cable will have conducting cores that are made mostly of aluminium with a very thin coating of copper on the outside of the core. These cables are called Copper Clad Aluminium (CCA).

Having these two different types of materials in the conducting core of the cable reduces the cost of the cable but it also significantly reduces the amount of data and power (when using power over ethernet - PoE devices) that can be transmitted along the cable and they also represent a fire hazard. That is why we will only use high quality cables that contain solid bare copper conductors.

Secondly, a good quality data cable will have an outer PVC jacket that is made up of halogen free compounds that are good fire retardants. The current UK British Standards (BS 7671:2018+A1:2020 - Requirements for Electrical Installations. IET Wiring Regulations) do not explicitly require cables in a domestic dwelling to be the type that produce low smoke or low halogen when they catch fire.

But we firmly believe that our client’s safety is of paramount important therefore we will only specify Low Smoke Zero Halogen (LSZH) for all our domestic installations. Whilst LSZH cables may cost slightly more, than the less safe standard PVC clad cables, we feel the LSZH cables are worth the extra investment.

Whilst not directly related to the quality of the data cables we also firmly believe in delivering a high standard of finish as part of our data network installations. For this reason, we specify BeadMaster products for all the data wall sockets.

BeadMaster products allow you to achieve a high-quality finish around the opening in the plaster of wall sockets. They reduce the need for re-work and snagging of the plaster around the opening of the backbox for the socket and prevent the cables inside the backboxes becoming wet or being coated in plaster when the walls are being skimmed.

5. Conclusion

A PARTNER YOU CAN DEPEND ON TO DELIVER EVERYTIME

Hopefully after having read this blog, you will appreciate that our comprehensive approach to data network implementations, from the design through to physical installations, provides our clients with long-term peace of mind.

If you would like to discuss securing a 25-year warranty for a data network installation for your project or even just a general smart home wiring requirement, please feel free to connect with us on the following link: Connect with us

It should be noted that Terms and Conditions will apply to the 25-year warranty, these are available on request.

Share:

Please feel free to share this blog if you found the contents useful or interesting